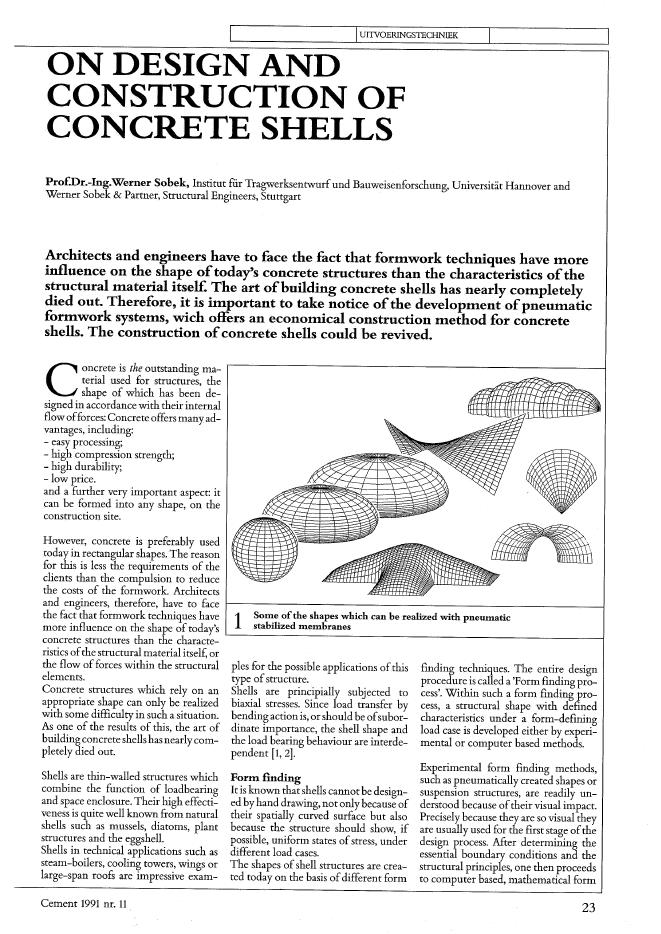

I !UITVOEmNGSTICHNlliKON DESIGN ANDCONSTRUCTION OFCONCRETESHELLSProf.Dr.-Ing.Werner Sobek, Institut f?r Tragwerksentwurfund Bauweisenforschung, Universit?t Hannover andWerner Sobek & Partner, Structural Engineers, StuttgartArchitects and engineers have to face the fact that formwork techniqueshave moreinfluence on the shape oftoday's concrete structures than the characteristics ofthestructural material itself. The art ofbuilding concrete shells has nearly completelydied out. Therefore, it is important to take notice ofthe development ofpneumaticformwork systems, wich offers an economical construction method for concreteshells. The construction ofconcrete shells could be revived.Experimental form finding methods,such as pneumatically created shapes orsuspension structures, are readily un-derstood because oftheir visual impact.Precisely because theyare so visual theyare usually used for the first stage ofthedesign process. After determining theessential boundary conditions and thestructural principles, one then proceedsto computer based, mathematical formfinding techniques. The entire designprocedure is called a 'Form finding pro-cess'. Within such a form finding pro-cess, a structural shape with definedcharacteristics under a form-definingload case is developed either by experi-mental or computer based methods.Form nndingIris known that shells cannot be design-ed by hand drawing, notonly because oftheir spatially curved surface but alsobecause the structure should show, ifpossible, uniform states ofstress, underdifferent load cases.The shapes ofshell structures are crea~ted today on the basis ofdifferent formpIes for the possible applications ofthistype ofstructure.Shells are principially subjected tobiaxial stresses. Since load transfer bybending action is, orshould be ofsubor-dinate importance, the shell shape andthe load bearing behaviour are interde~pendent [1, 2].Shells are thin-walled structures whichcombine the function of loadbearingand space enc1osure. Their high effecti-veness is quite well known Erom naturalshells such as mussels, diatoms, plantstructures and the eggshell.Shells in technical applications such assteam-boilers, cooling towers, wings orlarge-span raofs are impressive exam-However, concrete is preferably usedtoday in rectangular shapes. The reasonfor this is less the requirements of theclients than the compulsion to reducethe costs of the formwork. Architectsand engineers, therefore, have to face 1-------------------------------_;the fact that formwork techniques have 1 Some oftheshapes which can be realized with pneumaticmore influence on the shape of today's '--__s_ta_b_iliz_?_e_d_m~e_m_b_r~a-n-es _;concrete structures than the characte-ristics ofthe structural material itself, orthe flow offorces within the structuralelements.Concrete structures which rely on anappropriate shape can only be realizedwith some difficulty in such a situation.As one of the results of this, the art ofbuildingconcreteshells has nearlycom-pletely died out.Concrete is the outstanding ma-. terial used for structures, theshape of which has been de-signed in accordance with their internalflow offorces: Concreteoffers manyad-vantages, incl~ding:~ easy pracessmg;- high compression strength;- high durability;-lowpdce.and a further very important aspect itcan be formed into any shape, on theconstruction site.Cement 1991 nr. 11 23IUITVOERINGSTECHNIEK2The different principles ofpneumatic stabilisation ofa fabricmembrane:A: air-supported structureB: air-inflated bag, partiallywater-Hlledc: internal pressure below atmosphericpressureD: a series ofcnshions which areprestressed by reduced internalpressureE: air-inflated cushionF: an air-supported membrane, theshape ofwhich has been structured bycablesBA--~EcoFfinding methods.The most important experimental me-thods are:- suspension structures;- shapescreated byplastificationofthinsheets;- pneumatically created shapes.The computer based methods may besplitinto two groups: direct and indirectmethods [3].The direct methods are:- the solution ofthe set of(differential)equations which describes the mem-brane shell [1];- indirect methods in combinationwith optimization procedures.The indirect methods are:- the geometric non-linear finite ele-ment method;~ the forcedensity method;- methods based on vector analysis;- algorithms limited to certain geome-trie conditions.The direct methods facilitate the com-putation of the shape ofa structurewhich shows a prescribed state ofstressunder the so-called form-defining loadcase for a given set ofgeometric and sta-tic boundary conditions.Ir is important to note that the directmethods may not always yield aresuit,because the prescribedstateofstress andthe associated load case exdude any so-lution. The indirect methods may beused advantageously here because theyalways have aresult. However, the stateofstress within the shell, obtained at theend of such a computation, may varyfrom that required.Construction methodsThe curved geometryofa shell does notonly add a degree of complexity to thedesign process, it also makes the con-struction ofthe building more compli-cated. Concrete requires a formwork,the shape of which is also the shape ofthe shell. In addition, this formwork hasto carry the heavy dead weight of thefresh concrete.Conventional formwork systems,suchas shuttering with boards, are too ex-pensive to be used for double curvedshells. There are, however, only a fewmethods available which may reducethe costs for the formwork and therebybringback the buildingofshellsinro thebounds ofeconomic feasibility. Some ofthe most important of these alternativeCOllStruction methods are:- free cantilevering construction withcast-in-placeconcrete or precast ele-ments;- shotcreting onto a fine wire mesh net;- earth embankments as formwork;- use of pneumatic (air-supported)formwork systems.The current level ofknowledge indiea-tes that only the method of pneumaticformwork fulfills the requirements:- high level ofprefabrication;- quick erection and dismantling;- almost unlimited spatial curvatures;-large spans;- multiple use.Because of these interesting features,discussioninthis paperwill be restrietedto this type offormwork (fig. 1-2).Pnenmatic formwork systems forconcrete shellsThe history of pneumatic formworksystems goes back to 1936. Since that ti-me, a number ofdifferent systems and aseries of different erecrion-procedureshave been developed.Pneumatic formwork with rigid truss basis, byH. Heifetz243Italy 1938: Tnbular inflated formwork for theconstruction ofwater lines4Cement 1991 nr. 11formwork on the actual structure. Sincethe membranes are tightly curved, in-ternal pressures of up to 10 kN/m2arepossible. PVC-coated fabrics were usedas membranes (fig. 4).Partial or total fllling with fluids, e.g.water, also increases the stiffness of theformwork. In addition, fluid and air fil-ling allows one to enlarge the range ofpneumatically formabIe shapes (fig. 5).Whereas the application of high pres-sure systems is limited, a wide range ofstructures can be built by concreting insingle layers. This method was develop-ed as early as 1948 by Walace Neff, oneofthe pioneersofpneumatic formworkconstruction (fig. 6). Harrington uses thesame principle today. He lays asystem of'":: : .A system developed by Haim Heifetz,withwhich numerous smallershells ha-ve been constructed since 1960, inparti-cular in Israel, eau also be described as ahigh-pressure formwork system. Withthis system, the membranes are connec-ted to a rigid, easily transportable baseconstruction. The forces are thus 'short-circuited' within the system itself, sothat nothing need be done to anchor the

Reacties