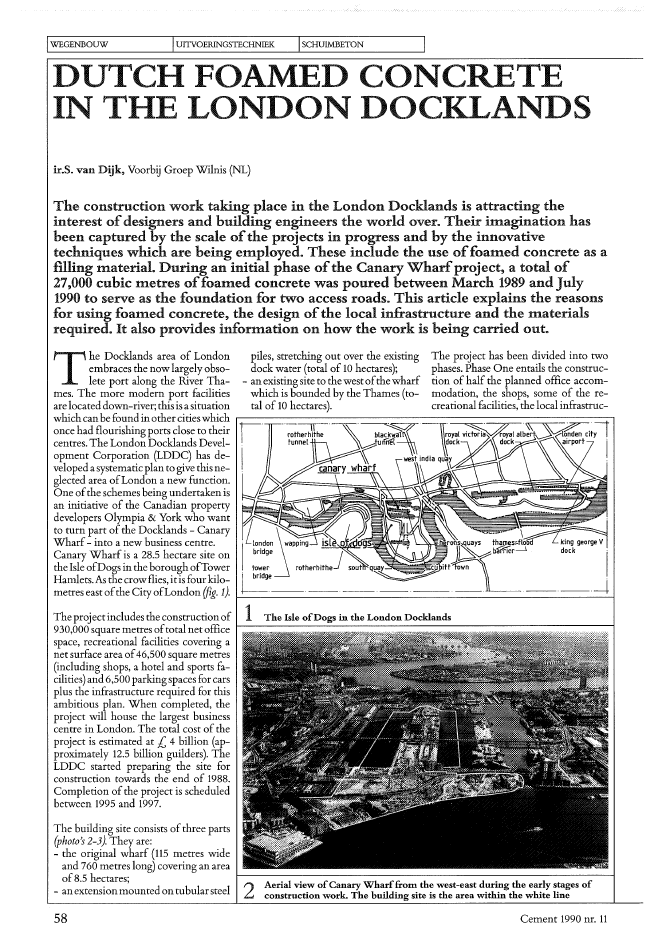

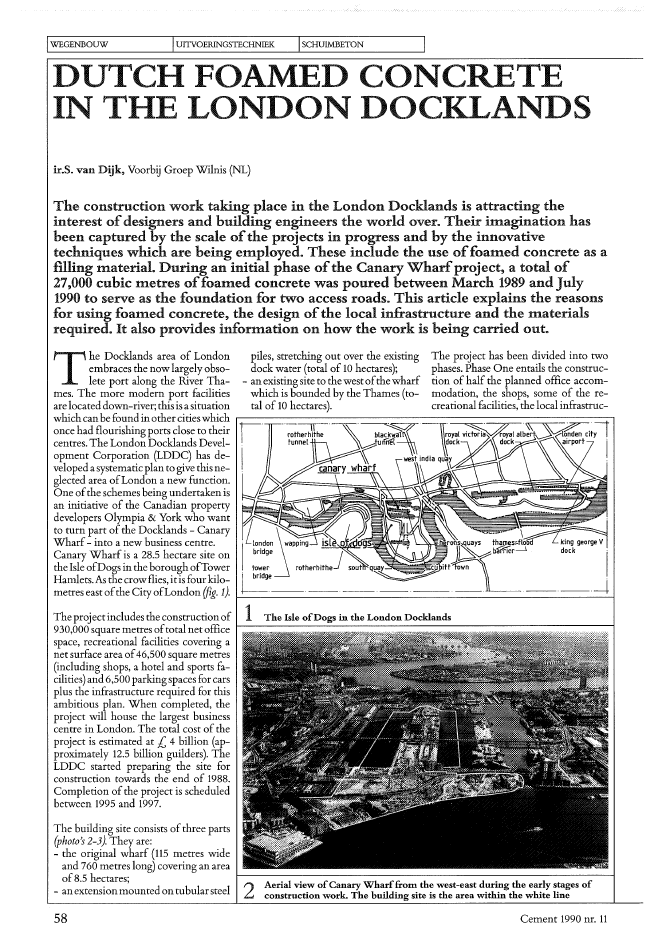

IWEGENBOUW IUITVOERINGSTECHNIEK ISCHUIMBETON IDUTCH FOAMED CONCRETEIN THE LONDON DOCKLANDS?r.S. van Dijk, Voorbij Groep Wilnis (NL)The construction work taking place in the London Doeklands is attracting theinterest ofdesigners and building engineers the world over. Their imagination hasbeen captured by the scale ofthe projects in progress and by the innovativetechniques which are being employed. These include the use offoamed concrete as afilling material. During an initial phase ofthe Canary Wharfproject, a total of27,000 cubic metres offoamed concrete was poured between March 1989 and July1990 to serve as the foundation for two access roads. This article explains the reasonsfor using foamed concrete, the design ofthe local in:&astructure and the materialsrequired. It also provides information on how the work is being carried out.The project has been divided into twophases. Phase One entails the construc-tion of half the planned office accom-modation, the shops, same of the re-creational facilities, the local infrastruc-piles, stretching out over the existingdock water (total of 10 hectares);- an existing site to thewest ofthewharfwhich is bounded by the Thames (to-tal of 10 hectares).The Docklands area of Londonembraces the now largely obso-lete port along the River Tha-mes. The more modern port facilitiesare locateddown-river; this is asituationwhich can be found in othercitieswhich [":;1==.;;:::::==::;:;:::=~~==:;;;;;;=;;:-=::;;=::::;;;:::::-=:;:;::=~~==-:;;:::==tlonce had flourishing ports close to theircentres. The London Docklands Devel-opment Corporation (LDDC) has de- Iveloped asystematic plan to give this ne-glected area ofLondon a new function.One ofthe schemes being undertaken isan initiative of the Canadian propertydevelopers Olympia & York who wantto turn part ofthe Docklands - CanaryWharf- into a new business centre.Canary Wharf is a 28.5 hectare site onthe Isle ofDogs in the borough ofTowerHamlets.As the crowflies, it is four kilo-metres east ofthe City ofLondon (fig. 1).The projectincludes the constructionof 1 The Isle ofDogs in the London Doeklands930,000 square metres oftotal net office 1---------=------------------------1space, recreational facilities covering anet surface area of46,500 square metres(including shops, a hotel and sports fa-cilities) and 6,500 parkingspaces for carsplus the infrastructure required for thisambitious plan. When completed, theproject will house the largest businesscentre in London. The total cost of theproject is estimated at L 4 billion (ap-proximately 12.5 billion guilders). TheLDDC started preparing the site forconstruction towards the end of 1988.Completion ofthe project is scheduledbetween 1995 and 1997.The building site consists ofthree parts(photo's 2-3). They are:- the original wharf (115 metres wideand 760 metres long) covering an areaof8.5 hectares; 1--------------------------------1_ an extension mounted on tubular steel 2 Aerial view ofCanary Wharftrom the west-east during the early stages ofconstruction work. The building site is the area within the white line58 Cement 1990 nr. 11The length ofthe piles varys from 12 to17 metres and the diameter is either 0.45or 0.6 metres with aworking load of900and 2000 kN, respectively. The safetyfactor is 1.5.The use offoamed concretewas seenas apossible solution to these problems.However, the building industry in theUnited Kingdom had litcle experiencein the production and processing offoamed concrete. This resulted in re-quests for information being sent to 17foamed concrete manufacturers in vari-ous countries. From the replies, a short-list was made and a small number ofmanufacturers - induding two Dutchcompanies - were interviewed.A contract was awarded to the VoorbijGroep (the Netherlands) on 16 Decem-ber 1988 for a sum of [, 780,000 (ap-proximately2.5 rnillion guilders) for thesupplyand casting of27,000 cubic me-tres of foamed concrete (for the firstphase of constructing of the accessroads) and for design consultancy,know-how and equipment. The decisi-on to use foamed concrete reduced thecosts ofthe piled foundation by a factorofthree to [, 500,000 (or 700 continu-ous flight auger piles). The VoorbijGroep set up acompany, Voton UKLtd.,to carry out the work and manage themateriais.propped condition for the constructionof a four-Ievel underground car park.Lateral soil pressure exerted by the roadnetwork on this retaining wall rnightgive rise to stability problems. Anotherimportant factor was the flXed locationofthe connections to the utilities.The structure of the road is shown infigure 4. On the piles, either a pile cap iscast (1 x 1 x 0.4 m3) or a concrete slab.The concrete slab has a thickness of0.4metres and is situated in places abovewhich there are hard construction ele-ments (such as sewers, sewer manholesand pedestrian tunnels) and in placeswhere the thickness ofthe foamed con-cretelayeris less than 1.7 metres (in con-nection with bending stress). Thefoamed concrete layer, which incorpo-rates all ofthe utilities, extends down to1.5 metres beneath the top side of theroad surface. The requirements applic-Design ofthe access roadsThe foundation ofthe roads consists of:- continuous flight auger piles used assubsidence-reducing skin frictionpiles;- a body offoamed concrete serving as a'raft foundation' between the roadsurface and the piles.1987, is situated to the east of CanaryWharf, only ten rninutes away by car.New roads are being builtand aBill is inParliamentfor the extensionoftheLon-don Underground rail system to thearea.From the outset, the designer knew thatthe road section would require a piledfoundation to avoid unacceptably largesubsidences. Moreover, the foundationhad to be maintenance-free for 150years, as the roads are going to be thearteries ofCanary Wharf and it wouldbe impractical to dig them up for repair.The use of sand as a fllling materialwould impose a large vertical load onthe existing foundation. Alarge numberoflong skin friction piles would be re-quired to prevent subsidence and thiswould mean high foundation costs. Ad-ditionally, it was deemed inadvisable touse light granular material as the tworoads are bounded over a long distanceby a retaining wal!, with deep excava-tionworkplannedononesideinthe un-Why foamed concrete was chosenTwo parallel access roads form the back-bone of the infrastructure. SOM en-countered a number ofproblems whiledesigning these roads.To start with, the design level of theroads is four metres above the existingground level. The existing foundation isliable to subsidence and the first load-bearing level - consisting of consoli-dated daylayers, sometimes with alayeroflimestone and marl- is, onaverage, 18metres below ground level.The first firm layer ofsand is, on aver-age, six metres deeper and the dockawater is between 1.8 and 2.3 metresbelow ground level..?'%~t~II:~;:~:~~~:~:?~~:~:::::ii[_[f[ttt[[[[i[lMilltw3 Artist's hnpression ofCanaryWharfand LondonThis phase is scheduled for completionin 1992. Ir also indudes the constructionoftwo parallel access roads ofabout 300metres long on the old site ofthe wharf.The first tenants are expected to occupythe buildings in 1991, which is whenPhaseTwo ofthe constructionworkwillcommence. It will see the completionoftwo 35-storeyoffice buildings and otherwork, induding the extension of thetwo access roads.By the time ofdelivery,a total of 25 buildings (induding twomore high-rise towers) will have beenerected. No less than 33% ofthe overallsite has been reserved for open spacesand pedestrian precincts.Improvements have already been madein respect of and further changes areplanned. The route of an unmannedoverhead railway systemputinto servicein August 1987 - the Docklands LightRailway (DLR) - passes through theheart of Canary Wharf. This is nowbeingextendedand upgraded.Therearealso fast river-buses which maintainlinks with central London. The LondonCity Airport, operational since OctoberBefore the project is completed, nearly[,1 billion will have been spent on im-proving the transport infrastructure inand the access to and from the east ofLondon.Together with the developer, LehrerMcGovern International is responsiblefor the construction management oftheproject. To back up the constructionmanager, there is a team ofconsultantsin charge of design and calculations.The firm ofconsultants which drew upthe guidelines for the overall plan -Skidmore, Owings & Merrill Associates(SOM) - also designed three buildingsand produced the plans and calculationsfor the local infrastructure.1----------------; The project has been divided up into anumber of parcels and a managementcontractor has been appointed for each'------------------' one. Bovis Construction Ltd. (BCL) isture and 3,000 parking spaces. In total, the management contractor for the in-seven office buildings as weIl as the cen- frastructure and for other parts of thetral retail building and station will be project. As such, they are accountable toputup in this phase.Among theseis 'The the construction managers and the con-Tower' which is guaranteed to be the sultants and they award contracts toeye-catcher of the project with its 50 sub-contractors.floors reaching 240 metres into the air.The other office buildings in this phasewill have between 12 and 14 floors.Cement 1990 nr. 11 59'-- 1UITVOERINGSTECHNIEK ISCHUIMBETON....:jlTIexist pile cap. :_. I -existing pile cap to remainor4------+-~of_600 mm concrete (type (25 NJon bottom and sidesI+H--+-+-++-+--+-trim and retain existing pilesJhu;Id;" U"'------~--- .200011400top of finished roadway ---t---r-4-.TIpi~e cap ~(ev, ~arie~Idrainage matting and filtercontinuous flight auger pilesor driven precast concrete -+-+-+~+-l--l-+-+-+-temporary retention system aspiles with cast. in_situ ,[abs ~--+H------+++----I-H-/----++ required by general contractorcompacted granular fill ---i;';:C:;;:';:70='7:'=:07:::7t.:-:7'70'":'":":~:"7:~:""':"'"-:-:--:-:""""-:-:--:-"""",,,,,,,,,,-,jtype ON . ".,','.' ..... ,'.'.foamed concrete class Bfoamed concrete class Aparcel line ------_t_4 Vertical cross-section, at right angle to the road axisable to this foamed concrete (A) are avolume weight of480 kg/m3and a cubecompressive strength of0.27 MPa after28 days, Over this, there is alayer offoam-ed concrete (B) with a thickness of 0.5metres, a volume weight of670 kg/m3and a cube compressive strength of0.87MPaafter 28 days. On top ofthis, there isalayer ofgranular mIwith a thickness of0.5 metres, and, finally, the tarmac layer,also with a thickness of0.5 metres.Due to circumstances, including the fallofthe separate sewerage system, there isa great variety of road sections. Thisshows in the depth of excavation, and,consequently, in the thickness of thefoamed concrete layer (A) which variesbetween 1.7 and 10 metres.The road section is confined every-where, either by a retaining wall run-ning along the sides, a building wallor aparapet on the existing quay wal!. Thewidth of the road between these con-fines is 11.4 metres at all places.Design of foatned concrete andtnaterialsFoamed concreteRaw materiais, available locally, wereexamined beforehand and tested fortheir suitability for use in foamed con-crete. Attention was focused on proper-ties suchas fineness, acidity, carboncon-tentand initialsetting time. The materi-als examined were: one type ofportlandcement, three types ofpulverized fly ashand limestone dust in two degrees offineness.The basic requirements during the pre-liminary examination for foamed con-crete typeAwere avolumeweight ofthefoamed concrete mortar of 500 kg/m3and a 28-day cube compressive strengthofatleast0.6 MPa. The preliminaryexa-mination for foamed concrete type Bwas scheduled for a later date.Various mixtures were tested in order tofind the optimum mixture for everyconceivable type ofweather (especiallythe 24-hour temperature). The suitabi-lity tests produced three-day cube com-pressive strengths of0.2 to 0.5 MPa, 28-day cube compressive strengths of0.8 to1.3 MPa and 91-day cube compressivestrengths of 1.25 to 2.0 MPa.MateriaIsThelogisticsintheoldwharfposeaprob-lem in their own right. A large numberofgoods are transported from and pro-cessed in a relatively small area; the in-frastructure is not equipped to handleall of the road transportations. By anystandards, the number of goods trans-ported is large.There is a ringway around the wharf -some ofit made ofBailey materials andextending out over the dock water - butit has only two exit roads. Therefore, theconstruction manager, whose responsi-bilities include on-site logistics, stipu-lated that as much transport as possiblemust take place over the river and that,due to the lack of space, the storage ofplant and materials on the wharf mustbeavoided.The plantwhichis transpor-tedbyroadconsistsmainoftruckmixers,concrete pumps, mobile cranes andearthmoving machines. To meet theserequirements, the Voorbij Groep devel-oped new equipment for the manufac-ture ofVOTON foamed concrete.Abargewas purchased (the 'Trintel', 640BRT, length 62 metres, width 7.75 me-tres) and it was completely rebuiltwithin the space of two months (fig,5).Various facilities were put into the holdfor the manufacture ofwet mortar, i.e.:- six silos with a total capacity of 330tonnes ofdry material;- watertankswith atotal capacityof120m3, for mixing water and ballast;- an automatic dosing and mixing sys-tem, the latter incorporating both adry and a wet mixer;- a double set ofsqueeze pumps;- a generator for the power supply.The barge was also fitted with everypossibIe convenience for the workmen,including a galley, showers, living quar-ters, cabins and recreation rooms. Thereis also a smalliaboratory and an office.The on-board facilities are sufflcient toproduce base mortar for 800 m3offoamed concrete with a volume weightof 500 kg/m3- without the need toresupply the barge. The base mortarproduced aboard the barge is pumpedthrough hoses to the foamed concreteunit on the building site over a maxi-mum distance of 150 metres.60 Cement 1990 nr. 117 The pouring systeIn for foaIned concrete;a vertical cross-section, parallel to the road axisA mobile foamed concrete unit wasmanufactured at the same time as thebarge was being rebuilt. This unit (fig. 6)is 6 metres long, 2.4 metres wide and hasan emptyweightof4.5 tonnes. Itis fittedwith a double set of squeeze pumps, adouble set offoam generators, a mixingtrough and a generator for the powersupply. The foam praduced by the foamgenerators is injected into the hosesbehind the pumps. Stationary mixers inthe hoses ensure the homogeneousmixing ofthe foam and the base mortar.The foamed concrete mortar is pumpedto the pouting place over a maximumdistance of150 metres.The foamed con-crete unit has a production capaeity of45 m3per hour, when making foamedconcrete with a volume weight of 500kg/m3?Speeifications forthe production, appli-ance and curing of foamed concretewere drawn up for the managementcontractor, BCL, as in the United King-dom, - unlike in the Netherlands - thereare no regulations or directives coveringfoamed concrete.Work on the projectThe contractor for the raads and utili-ties, CJ. Pearce & Co. Ltd., manufactur-ed the shutters and other facilities requi-red for the pouring offoamed concrete.The casing ofa pour is relatively simpIe,because, lengthwise, the raad section isconfined between retaining walls or theboundaries of premises. This meansCement 1990 nr. 11The Inobile foaIned concrete unitday_3day_3day_2day_lday_361I_WE_G_E_NB_O_UW I UITVOERINGSTECHNIEK8-9 View ofwork in progress on the roadI SCHUIMBETONshutters are required only at right anglesto the retaining walls. With a step-by-step approachwith the foamed concreteon successive pouring days, it is possibleto make repeated use ofthe same shut-ters and the set foamed concrete forms anatural shutter wall. This can be seen infigure 7, in which the numbers refer tosuccessive pours. Photographs 8 and 9show work in progress.Theshutterswereremovedonthemorn-ing after the pouring day and during thesummer months on the actual pour-ingday.Atthetimeofremoval,thefoam-ed concrete is strong enough to walk onand after two to three days it can takeheavy vehicles. The average pour quan-tity per working day was around 150 m3with a layer thickness of0.5 to 1 metres.At a small number ofsurface locations, alayer thickness of1.5 to 3 metres was ap-plied.The barge is re-supplied in the eveningat Heron Quays, located parallel to thewharf, in order to avoid overloading thewharfwith vehicles.As the project progressed, everybodyconcerned became increasingly enthu-siastic about foamed concrete and thiseven resulted in the modification oftheoriginal design. Originally, two types of62foamed concrete were planned, AandB,which differ in volume weight andcompressive strength. The strength andbearing capacity of type A (with a vol-ume weight of 500 kg/m3) were morethan sufficient to enable the greater vol-ume weight (type B) to be dispensedwith.All utilities,with the exception ofpowercables, were covered straightaway withfoamed concrete. At places where theoriginal plans calledfor temporary sheetpiles, it was decided to dig a slope. Theexcavationwaslaterfllledupwithfoam-ed concrete.The material alsohad its ad-vantages for the road contractor: foam-ed concrete is soft enough to dig in andyet strong enough to be able to drive inshutter props. Other advantages offoamed concrete are that it fills up holesand irregularities and it is ideal for thepurpose of insulating permanent shut-ters for a concrete pour.Quality controlVoton UK Ltd. checked the quality ofthe foamed concrete by regularly mea-suring the volume weights of the basemortar and foamed concrete mortar.Additionally, test cubes were produced(one set ofthree for each 100 m3offoamed concrete mortar) in order to determi-ne the cube compressive strength atages of14, 28 and 56 days.Averagevaluesfor the compressive strengths were 0.7MPa, 1.1 MPa and 1.3 MPa, respectively.A company called Messrs. Sandberg wasresponsible for inspecting all the mate-rials used on the building site and theyalso produced test cubes made offoam-ed concrete. According to informationsupplied by Sandberg for the periodfromJuly 1989toJanuary 1990, theaver-age cube compressive strength was 1.1MPa (coefficient of variation 20%) andthe volume weight was 483 kg/m3(coefficient of variation 6.3%), bothmeasured at an age of 28 days.All in all, the first phase ofthe road con-struction went weIl and the project hasalreadyhad abig spin-offfor theVoorbijGroep, both in the Netherlands and inother countries. Moreover, negotiationsare in progress for the second phase ofthe project.References1. Ground Engineering, September 1988,November 1988, March 1990 and April19902. New Builder, December 19893. New Civil Engineer, June 19884. Time, April 1988Cement 1990 nr. 11

Reacties